About us

Company History (Since 2004)

ADVIK started in 2004 as ‘Advik International’. We were a small company then with only 3 employees and few orders in hand. Slowly but steadily we increased our customers base and our range of products.

In 2007 we renamed & restructured the ownership to ‘Advik Incorporation’ to invest more money and build better setup.

In 2009 we exhibited at EFTTEX, Budapest, Hungary and we received a massive response from our visitors. Our product range, quality, pricing and service policies were well received by them and we established ourselves as a major supplier of sports fishing tackle to the European market.

With a good customer base we kept on expanding our range of products and strengthening our services ensuring that we were one of the better known suppliers in the fishing industry when it came to quality of products and services.

We then appeared at Efttex 2011 in Amsterdam and EFTTEX 2014 in Brussels. The only reason for us to take breaks between each of our appearances at EFTTEX was that we were spending more time and resources in developing new products and ways to provide better services to our clients. This in turn was getting us a good client base and we felt that the show was required only when we had a good development curve before our next appearance.

In 2017, once again we restructured & renamed the company to ‘Advik Sports Fishing Products’. Also, we moved to a better location to be able to process more orders and to add more services to what we already offered. In 2019, we exhibited under the new name at Brussels, Belgium and received massive response from our clients. Our order volume increased abruptly and in 2022 we have again moved to a much larger space with many facilities that will improve our turn around time, quality check and packaging.

By now our products and staff strength has grown manifolds. Our future goals are to ensure that we constantly update our systems so that we can adapt to the changing demands of the market. Additionally, as always product development and improvement in services will always remain our priority. For us, our customers have always come first and so will they in future.

Our Supply Base

- Belgium

- Bulgaria

- Czech Republic

- Denmark

- Finland

- France

- Germany

- Hungary

- Italy

- Latvia

- Netherlands

- Poland

- Romania

- Russia

- Slovakia

- Spain

- Ukraine

- United Kingdom

- USA

Our Management

Vikram Paharia

Partner

Director - Product & Process R&D Creative,

Development, and Finance Management

Ruchika Paharia

Partner

Director - Business Development,

Sales & Customer Relations

Roshan Rungta

Partner

Director - Production, Branding,

Packaging & Order Dispatch Mgmt.

Company Policies

- Customer Satisfaction

- Constant Product Quality Upgradation

- Innovation and regular addition of new products to the range

- Economic and Competitive Pricing without compromising quality

- Latest Packaging Techniques

- Custom Branding

- Constant Improvement in Products & Services by listening to our clients

How do we manufacture?

We believe in a collaborative manufacturing setup. It is a fact that the Sports Fishing Accessories Product range has such a huge variety that it is practically impossible for a single factory to manufacture everything on its own. Therefore, along with manufacturing some major components ourselves, we partner with some workshops and factories that specialize in making parts of our products. This in turn helps us in delivering a huge variety of products on time and at very economical prices.

Main components of all products are made at our own setup. Ancillary parts like swivels, catapult elastic, clips, foams etc. are sourced from factories that make these parts in bulk. At the same time small metal parts like Tops, Screws, Adaptors, handles etc. are made in workshops with skilled craftsmen who are doing such tooling on a regular basis.

Finally, we bring together everything under our best supervision to complete the products and supply them to you at the best possible prices and with the latest packaging standards.

Manufacturing Materials & Processes

Injection Moulding

Semi-automatic Vertical Injection Moulding

The most versatile and widely used way of moulding plastic & rubber items. Semi-automatic vertical injection moulding machines are best when we have to manufacture a large range of plastic items in a decent quantity because it is easy to change moulds frequently or customize the materials and colours with less wastage.

At the same time these machines give us good flexibility of changing inserts and metal parts that need to be incorporated in the same plastic product.

Most of our plastic products are moulded in these machines with high accuracy and productivity.

Manual Moulding Machines

A very old method of moulding where the pressure and clamping both are manually controlled. But this is an under-estimated process where we are allowed to produce plastic products in low quantities, which is the most important reason that these are still used in manufacturing accessories. Basic mould items that have an easy shape and are small/medium in size are best suited for such kind of moulding.

Horizontal Automatic Moulding Machines

The most advanced technology in plastic injection moulding. Horizontal moulding is best when used for large and heavy plastic products, or when smaller products are required in huge volumes. When it comes to our sports fishing industry, we use these for heavier items like Plastic trays, Catapults, Crushers, Rig Bins Bait spoons and similar products.

Plastic Materials

Polypropylene (PP)

Polypropylene (PP), also known as polypropene, is a thermoplastic polymer used in a wide variety of applications. PP is the commodity plastic with the lowest density. With lower density, moldings parts with lower weight and more parts of a certain mass of plastic can be produced. These are available is a massive range of colours and can also be customized easily as per the product’s requirement.

It is amongst the most economical form of plastic and widely used in Sports Fishing accessories due to the high demand for products which are of acceptable quality and economical at the same time.

Nylon Plastic

A much stronger variant of plastic and almost doubly expensive than PP, nylons are used for manufacturing parts that require to be sturdy and carry heavier weights. Products like Bankstick Tops (that take a lot of Hammering), Tripod adaptors, Seatbox Accessories, Rodpod Adaptors, Indicator Heads, Lead clips and similar items where the material strength is of utmost significance.

Low-density polyethylene (LDPE)

A softer version of plastic, LDPE is used to make products that require some extent of bend or stretch to accomodate certain functions. For example, some feeders, lead inserts, clips, stoppers etc. are made in this material. Even some rod rests are made in this material so that they can expand and contract. LDPE is an economical material and a close cheap substitute for rubber in some cases and a preferred substitute for PP in some cases.

Low-density polyethylene (LDPE)

A softer version of plastic, LDPE is used to make products that require some extent of bend or stretch to accommodate certain functions. For example, some feeders, lead inserts, clips, stoppers etc. are made in this material. Even some rod rests are made in this material so that they can expand and contract. LDPE is an economical material and a close cheap substitute for rubber in some cases and a preferred substitute for PP in some cases.

Rubber Materials

High Purity Rubber Granules

Used in our High Quality Rod Rests, Terminal Tackle, Needle Grip coatings these high purity rubber granules are moulded for increased flexibility and durability. They provide an anti-slip feature to our needle grips.

A commonly used more economical alternative is rubber mixed with impurities. We avoid using such inferior materials because after certain amount of stretch the impure material products break apart. But, if the product need to be really cheap then such measures are standard.

Silicone Rubber

Silicone is a more stretchable and versatile version of rubber. Used in making rubber products with a sifter feel, high stretch and vibrant colours, silicone is good for making catapult rubbers, feeder moulds, terminal tackle, rod rests and similar products.

Although a much more expensive than rubber, silicone is gaining more & more popularity since last few years due to its quality and wide range of uses.

Metal Workshop Machines

Capstan Machines

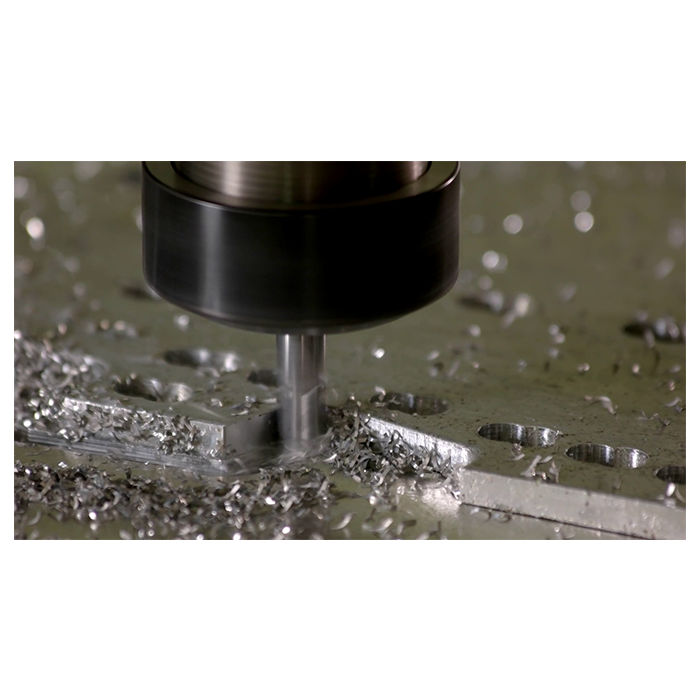

A capstan machine is a processing machine used to make the same parts again and again. The cutting bits are mounted on a rotatable turret known as a capstan, which permits the client to rapidly change the introduction of the bits for slicing without needing to take off the first bit and afterward mount the second. A bit of crude material, off and on again known as a clear, is mounted into the capstan machine and is then spun at high velocity. The cutting apparatuses, some of the time known as blades, are then used to slice into the clear to make another shape or outline.

Machines are suitable for batch production of small components & secondary operations requiring Turning, Drilling, Grooving, Threading, Boring, Recessing, Forming etc. with semi-skilled operator.

We use them for making parts of metal items like Banksticks, Buzz Bars Adaptors, Hangers, Rod pods, Hi pods, Metal Rod Rests etc.

Drilling

Vertical / Horizontal Drilling procedures are a very frequently used part of manufacturing metal items. We use drilling to cut threads into sticks, tops, adaptors and many other metal parts. At the same time drilling is required when cutting holes or making hollow sections in solid metal parts.

An essential in metal manufacturing, we always ensure that good quality and accurate drills are used to keep the end product functionally sound.

Shaving

Shaping up of solid metal rods, such as a flat face of the Bank stick rod insert or a flattened surface of the Metal Butt Rests, demand a skilled metal shaving workmanship. This is largely dependent on the skill of our workmen who have been carrying out the process since years and are now so well versed with the shaving process that they barely go wrong.

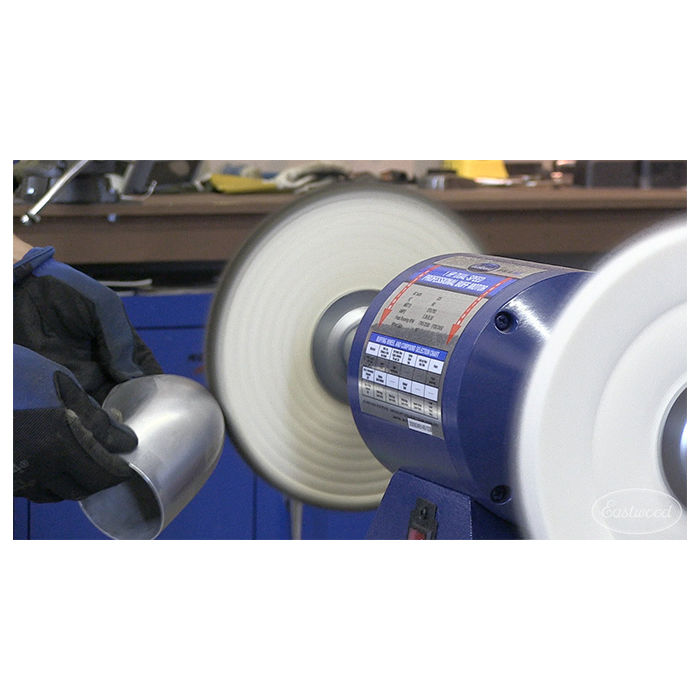

Polishing

No Stainless / Aluminum product is complete without being taken to the polishing machine. We either polish the finished product to perfection or we sand the surface to make it smooth enough for a perfect coat of paint.

Another manual job that requires a great deal of workmanship.

Metal Colouring

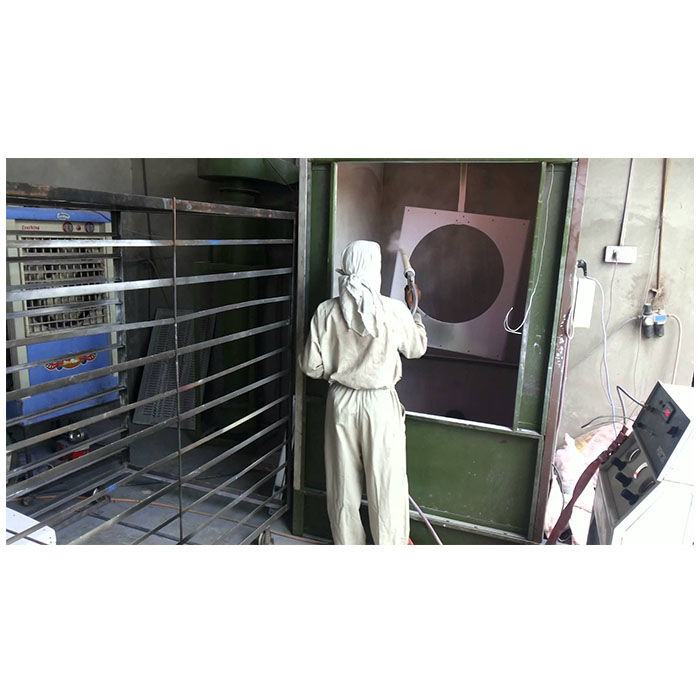

Powder Coating

A widely used method of painting metal items, Powder - coating is a type of coating that is applied as a free flowing, dry pow der. The main difference between a conventional liquid paint and a powder coating is that the powder coating does not require a solvent to keep the binder and filler parts in a liquid suspension form. The coating is typically applied electrostatically and is then cured under heat to allow it to flow and form a "skin". This creates a hard finish that is tougher than conventional Paints.

Metal Anodizing

Anodizing is an electrolytic passivation process used to increase the thickness of the natural oxide layer on the surface of metal parts.

We use anodizing to colour Aluminium products. Al though more expensive than powder coating, this process of painting aluminium products increases the life of the product and gives them a more premium look & feel.

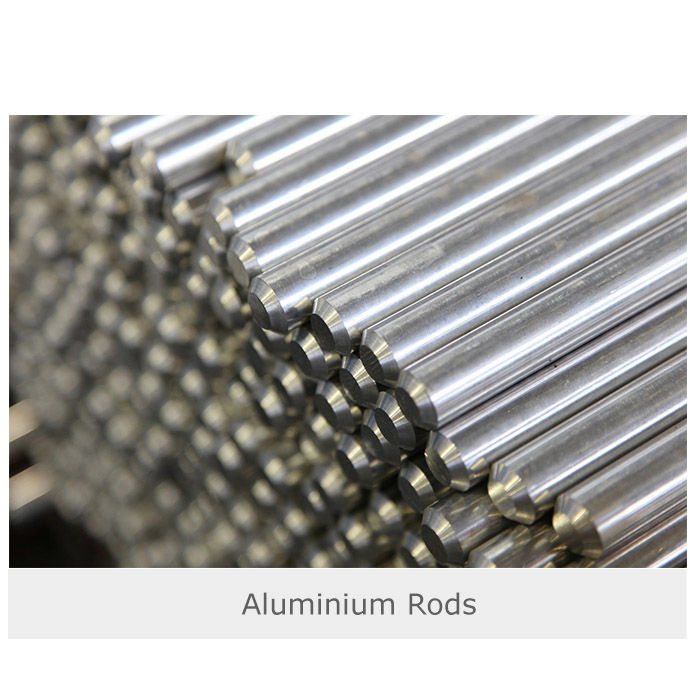

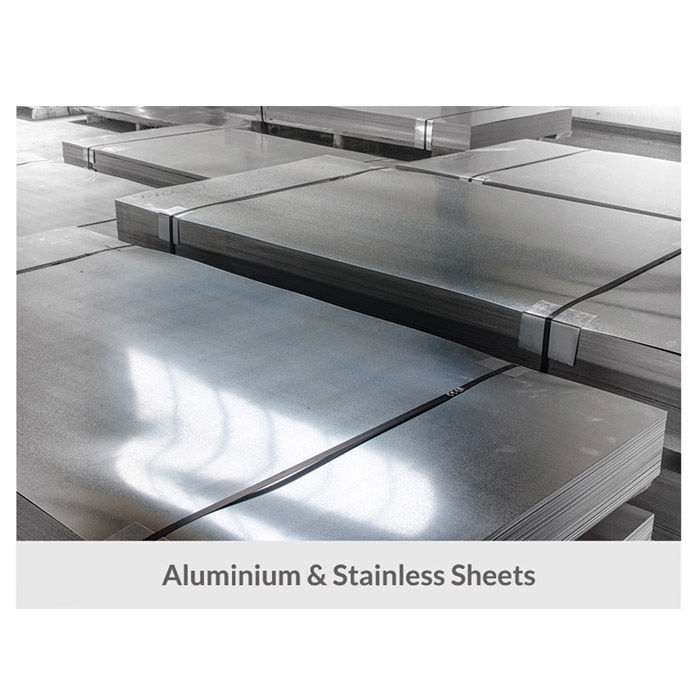

Metal Materials

We source high quality Tubes, Rods, Sheets and other forms of Aluminium, Stainless Steel, Brass, & Mild Steel Alloys from some of the most economical and good quality factories in India. Sourcing in bulk ensures that the products are cost effective and a direct from factory approach keeps the quality standards under control.

We work with custom sizes and custom composition of metals, to fit in the vast range of accessories throughout the catalog.